About us

Quality

Colson X-Cel Ltd manufacture a quality valve product to the highest level of precision engineering at the Advanced Manufacturing Park in the UK. This is achieved through our continuous improvement processes under ISO 9001, ISO 45001, ISO 14001 and is headed by our in-house quality manager and health and safety group manager.

Colson X-Cel Ltd manufacture in house, which ensures that we control the manufacturing process from placement of order to delivered valves. All processes are under one facility, one management and one ISO philosophy, which creates a culture of operational excellence. We strive to improve performance through continuous improvement, empowered employees, customer satisfaction and efficient resource management.

Colson X-Cel provide raw materials for all valves that are traceable to the original source mill and are supported with an EN10204 3.1 certificate or “mill certificates” that confirm the original production mill and any mechanical and chemical results. We ensure that through the entire process of manufacture that our valve components and complete valve are traceable to the original mill source. Colson provide a high level of transparency throughout the supply chain.

Integrity

Integrity is more than a value at Colson X-Cel. We create trust and valued relationships with internal and external stakeholders within our business. We do what we say and say what we do.

Experience

Our quality brand and product has stood for over 30 years as a leading manufacturer who is approved by super major end users such as Shell, BP, Exxon and ADNOC. Our reference list is extensive with a supply of quality engineered valves to worldwide end users.

We design, we machine, we assemble, we test, we quality assure, we deliver.

We are Colson X-Cel!

Design

Colson have over 30 years of valve design experience and knowledge in the industry. We have a team of highly qualified engineers who design our products in-house using the latest software and hardware, which creates 2D and 3D models. Our engineering team have a wide level of experience from 35 years to apprentice level, which ensures sustained knowledge and skills remain with our business. We design to the latest internationally recognised standards such as ASME, API, BS, EN and EEMUA. These standards compliment end user specifications to include valve narratives, project specific data sheets and piping specifications. Our quality is designed in.

Machine

Colson X-Cel Ltd machine in house at the Advanced Manufacturing Park in the UK using state of the art CNC machines. We use pre-programmed software to produce high level valve components to detailed drawings with precision accuracy. Our in-house machining improves the quality of our valve products with direct communication between the design, engineering and quality team, whereby we are all invested in the final outcome. This in house processes ensures timely delivery of the product.

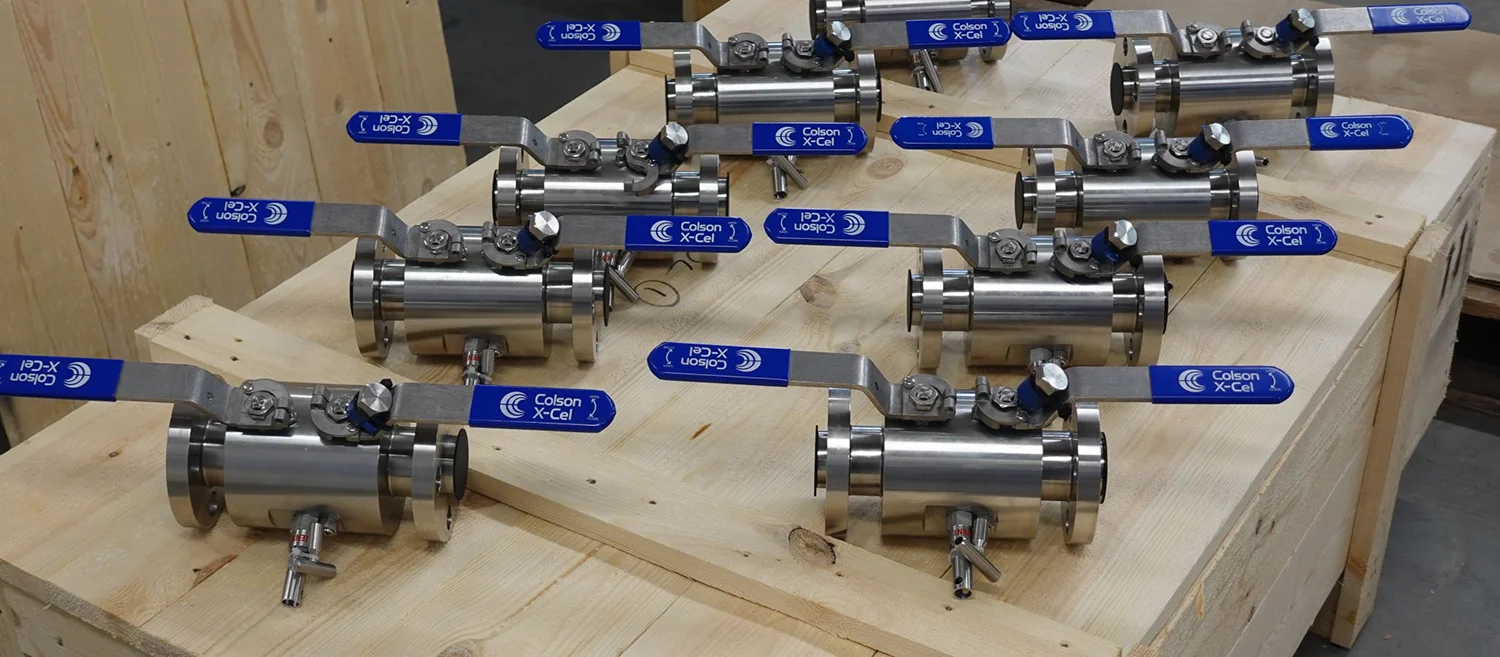

Assemble

Our dedicated assembly team are experienced and trained to fit valves to a high-level utilising standard operating procedures and Quality check lists. We ensure that each and every valve assembled is recorded and signed off to show full traceability throughout the process. Our records provide the ability to continuously learn and improve our processes to an ultimate quality product.

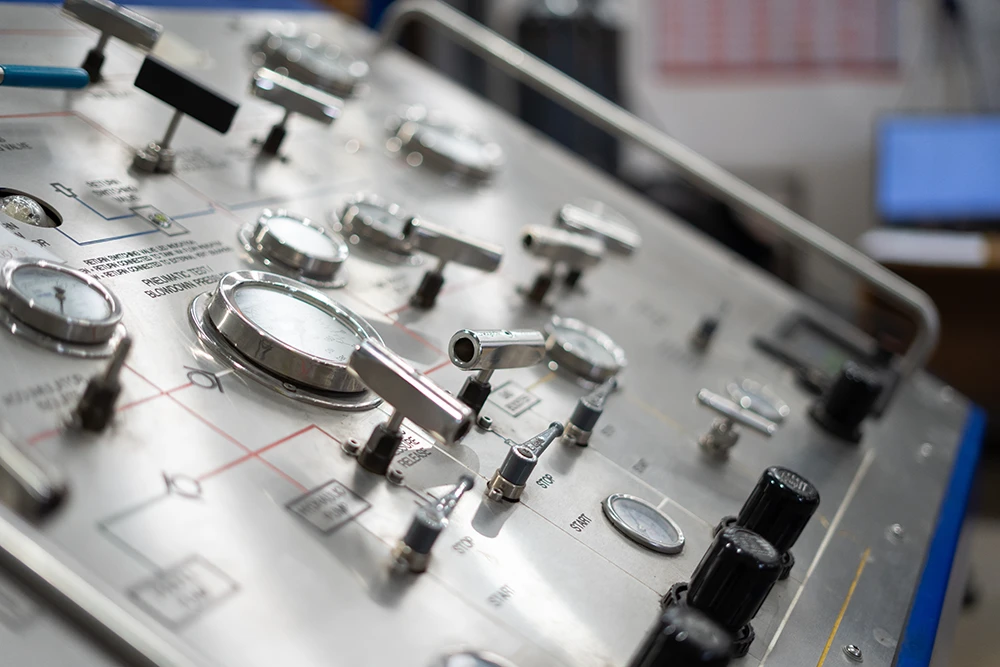

Test

Colson X-Cel Ltd test valves to industry standards such as API-598 and API-6D. We hydrostatically test valves as standard but can offer additional testing such as gas testing, low emissions testing, cold temperature testing (-46 °C) and cycle testing. We work to testing standards from API, EEMUA and ISO. These tests are conducted by our experienced team in our recently refurbished testing area, which is the corner stone of our continuous improvement plans. All testing can be witnessed by a third party, contractor or end user to validate our procedures and testing records. Colson X-Cel Ltd prides itself on a quality engineered valve product that seals first time, every time.

Quality Assure

Colson X-Cel Ltd prides itself on the ability to provide a quality, reputable, repeatable and reliable product. Throughout our manufacturing processes the quality is built in and we never let it out. We also encourage end users and customers to audit our processes and facility to ensure compliance with any specific requirements and to provide a clear level of transparency. On a regular basis we allow third parties, end users and contractors to witness test valves or conduct a final to review before goods are despatched. In addition to any customer specific audits, we are ISO approved to 9001, 45001 and 14001.